Frequently Asked Questions

Yes, normally we make changes in printing as per the wishes of customers. For such types of things, you can always contact our representatives on toll-free numbers (505) 407-0095 or can correspond via registered email sales@clawscustomboxes.com. Making changes multiple times makes us create new printing plates all the time. Therefore, for making changes in designing and artwork, additional charges are included /levied upon each time. But to know exactly your order you can get your quote today.

Yes, we offer this facility to our customers. All the pictures, text, and printing done by our company are crystal clear and visible. We can even send you text printed on the carton as a sample right now.

No, we don’t sell corrugated boxes right now.

It depends on the requirement of the customers how they want their shipping done. We pack the boxes in large cartons. The number of cartons can be varying as it depends on the size of the carton. While packing they are placed in corrugated boxes in a flat position. Mostly our customers tell us how they want their order to be delivered. Moreover, we don’t add shipping costs until it is requested by the customers. For smaller orders, we utilize United Parcel services. Therefore, we shipped folded cartons safely on your doorstep without extra and hidden charges.

It is a process or technique used by printing and packaging companies to get a 3-D shape. Emboss means to create recessed or relief images on paper or suchlike stuff.

We print cartons from both inside and outside. We run the carton through the press first for printing inside and then the same procedure is repeated for outside printing of the carton.

Right now we can print in full color options. The coating is also included in the whole digital poof. Normally with 4 colors process, fine printing can be done and the desired result can be obtained. But for more colors, we run through carton from printing and work hard to meet the wishes of customers and try to get the color scheme as it is demanded by the customers.

Window patching is sort of boxes that show the product which is inside it through plastic covering. This type of boxes helps the customer to see with their eyes, the product they are going to buy without opening the box.

Soft-touch coating as from its name appears is a soft coating that is adhesive and gives the soft and velvet-like look and texture. It dries up quickly without taking much time, which is good for the printing process that can be done within a given time. It does not get taint with the touch of fingertips, neither it changes its color into yellow with time. This coating is known as sophisticated and luxurious because of its exceptional result. Moreover, this coating is eco-friendly. It means it does not leave a bad impact on the environment and is not harmful to ozone layers.

Varnish

The varnish is a very small and thin coating used for protection purposes. In varnish coating sort of ink is used which has no color at all. It is known as a durable coating that’s why applied mostly on wooden or hard surfaces. It is not a specific formula rather it is made up of resin and dried oil. The constituent helps to maintain a great coating and stays there for a longer period. You can go for flood varnish or spot warmish as according to your needs. Flood varnish covers the whole printing page, whereas spot varnish is on some specific parts and particular areas of printing. Spot varnish is commonly used for highlighting the logo and brand name. It is available in gloss, matte and satin.

UV coating

The ultraviolet coating is done by passing ultraviolet lights. It dries very fast and hardens the coating within no time. It is considered a more durable and suitable coating that lasts long as we compare it with other coatings like varnish, Aqueous and soft-touch, etc. Spot UV gives exceptional outlook and catches the eye at once. It is the most protective coating but many people say that it is too shiny. And one more thing it can tear because of the hardness of the coating therefore, it needs special attention and skills of the professional before going to opt it.

Aqueous coating

This is the most cost-effective and best coating as it gives subtle and fine finishes to the printing. It is a water-based coating that is eco-friendly and in the benefit of the environment. It does not create any damage like; cracking, tearing, wrinkling, and creasing. It is also available in matt and gloss coating. It is highly recommended by the manufacturers because of its unique appealing and various advantages. It is far better than varnish and UV coating. It is known as greener coating as well as more durable with great resistance. It is mostly used for mail items, business cards, and brochure that resides in the wallet and come in direct contact. Aqueous coating either it is gloss or matt gives a specific surface that works as great resistance for pollutant factors.

Theses above-mentioned are a few coating that is done by our company. We apply different techniques to give the best coating and fine finishes to the product. We try to increase the sale of the product by offering a high quality of packaging and printing with supreme and best coating, either it is matte, or gloss, extra attention is given to bring the best end-result.

There are many steps involve in preparing folding cartons. For example,

Different design layouts are prepared.

- Than Repressing is done with the help of machines. It means different sheets are unrolled and cut according to the requirements

- Than sheets are cut keeping the designs in view. This process is called die making.

- Than it comes printing which is the main step.

- After printing is completed manufacturers start cutting and creasing the sheets according to the given measurement

- After completing printing and cutting, recycling is started to minimize the wastage

- In the end all the sheets are glued t gather to give the final shapes to the carton.

- The other name for process color is CMYK which tells about four basic colors like cyan, magenta, yellow and black. These basic colors are used to make all other colors through concentration and the process of saturation. On the other hand, the Pantone Matching System color is a particular color scheme that uses exceptional ink according to the numbers given in the chart. It’s a bit technical and involves more cost and money as the colors appear exactly you want them, unlike colors that are shown on the screen of computers. Both are good color schemes and equally useful. It depends on the choice and depends on the nature of the product. For instance, the Pantone Matching System color is regarded as more expensive but it is appropriate for the food and liquid industry. On the other side, the process color is suitable for lightweight items.

Folding carton is a three-dimensional type of container. A thick layer is used in its making; these boxes are not like shoe boxes. They cannot be folded. These boxes have their top and bottom surface and they are like corrugated boxes.

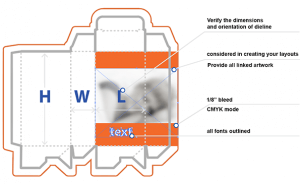

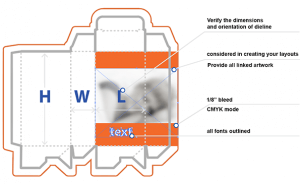

As its name shows pre means “before” and press mean printing. After finalizing the designs the manufacturers think about its digital printing procedure which involves the following steps and this entire task is done on the computer. The process may differ depending on the nature of the file but mostly these common steps are done.

- Fonts are checked and set according to the required size

- They make changes in the graphic designs.

- Camera-ready artwork is completed

- Then comes color separation by using the proper formula

- Crop marks are included

- Pages are put in the order for taking prints easily

- Prepress proofs are taken

- Lastly?/finally they get film and create printing plates

It stands for Solid bleached Sulfate. This type of packaging is mostly used in the food and beverage industry. Very little recycled material is used in making these paper board boxes. These sbs boxes are ideal for graphic printing because of their less stiffness.

It depends on the order of the boxes. Sometimes it is in bulk or sometimes less quantity is required by the customers. Therefore, we can provide an exact turnaround when you provide us complete information regarding your order. But mostly, we take very little time, a maximum of 3 to 4 weeks on normal order.

It all depends on the nature of the order. Mostly, we always meet our deadlines. But the full cooperation of our customers is needed. Its because they are responsible to approve all the artwork and final designing. For this, we always look up for prompt response to finish the task timely. But overall, on standard orders, we take not more than 15 days and for rush order, we take 5 to working days after finalizing all the artwork and die line.

How to order

Our company sorts all the boxes into different categories so that customers’ could book their orders in less time and get the quotation without surfing so much on the net. To minimize the distraction of the customers, three options are available on the site with the name;

- By style box

- By industries

- Custom style boxes

First, you have to log in to our page, then you will be able to make all sorts of changes for getting the desired size and shapes of the boxes.

By Style, boxes are those boxes which showcase all the designs done by our expert team. In these boxes, you can make your personal choices by getting a login on the page. You will get free die line designs here.

Next is by industries all the products are chosen here by the team of technical and sales professionals who offers you free die line and designing. Our skillful professionals work with you till the end, so that your dream comes true and you find good packaging solutions here. You will see different options to select from like size, color, dimension, and style, and when you will opt the desired or required one you will get the price, cost, and quantity side by side. You can save the changes and put them in the cart for later use.

The third one or the last one is custom style boxes; here you can select only length and width as these custom boxes do not come in the cube or other suchlike shapes. You have to select the options, save them, and put them in the shopping cart. You can reserve them for later usage in this way.

After finalizing artwork and die line designing you can imagine that you have covered a long milestone and reached the final step now.

If you have saved your quotation, then now you have to move on the shopping cart page, from there you can check your reserved data or quotation, you can edit the file and can make changes, and you can add your desired artwork or the styling you need. Then press “check out”.

Now it’s almost done, your order has been registered at Claws custom pipeline list. The next responsible/ in-charge department will take the charge, after prepress and confirming everything with you, will ship your order on the registered address within 6 to 7 working days.

Your order is completed. You can go on” My account” or can check ‘My order block’. You will get all the relevant information there. You can log in on Claws custom to know further about your order.

How to prepare artwork

Two main file formats that are Ai and PDF adobe reader are accepted.

We send press digital files via email. If you need a hard copy we will send you extra charges. Moreover, for physical proof, we will require PMS colors or the previously ordered boxes. PMS color is used on paper boards either they are coated or uncoated.

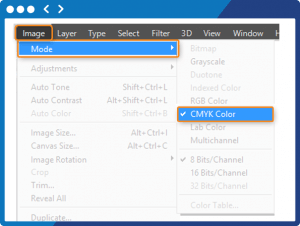

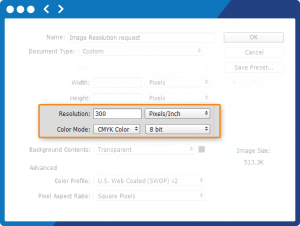

As told only CMYK colors are acceptable. If you provide any other color, like Pantone or RGB we change it, but while shifting the colors it can appear a bit different. Therefore, before finalizing any artwork we suggest you read all the process that is used by us for changing colors.

No, only theses two format files are recommendable. Adobe Photoshop® CS, Adobe Illustrator® CS, Adobe InDesign® CS-Only these two software programmers are used by the company and only files from these are acceptable.

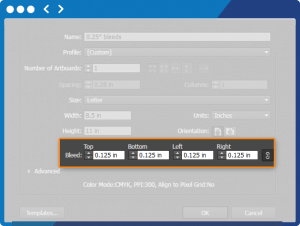

Bleeds are done if all the sides are in white but it is not compulsory all the time. We ask you to read our file preparation before finalizing bleeds for your final artwork and design. Claws Custom need 0.125″ bleed around the perimeter of your artwork for accurate cutting (e.g., artwork for a 4″x6″ postcard should extend to 4.25″ x 6.25″)

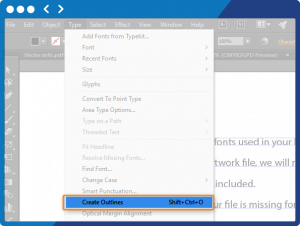

You need to convert all the text outlines before submitting us your artwork design file. For any clarification and guidelines, you can always check our prepared file to understand it well.

- In the ai or pdf file

- Images need to be of high-quality

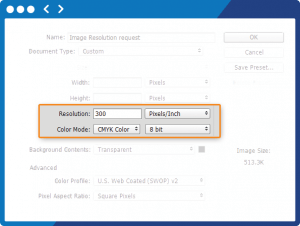

- Uncompressed 300 dpi resolution, 8 bit, Good resolution images will be accepted

- Only CMYK color mode and perfect font outline need to be provided by you.

- First, you should know about the die line of your artwork.

- To create layout check keenly about any wrinkle, crease, and folding of the boxes

- Always use CMYK mode.

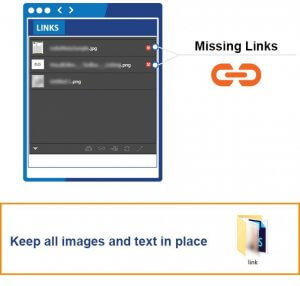

- Without embedding the images provide all suitable fonts and desired artwork.

- First, you should know about the die line of your artwork.

- To create layout check keenly about any wrinkle, crease, and folding of the boxes

- Always use CMYK mode.

- Without embedding the images provide all suitable fonts and desired artwork.

- Resolution should always between 150 Dpi and 300 Dpi. These are maximum and minimum ranges at the final 100% size.

- Don’t use low-resolution pictures and images.

Gradients are useful for producing effective and desired results in printing. Gradients can be used in file through vector and Raster. Before submitting your final draft and final artwork, we highly suggest and recommend you check and read thoroughly our given guidelines.

It is crucial to receive all fonts used in your layout. If you are unable to provide us fonts in your artwork file, we request you to resubmit the file with accurate fonts.

If your file is missing fonts, open your file in Illustrator, select “Create Outlines“, save fonts, re-save your artwork file, and then submit us. Otherwise, you can also open your file in Photoshop, select “Flatten the Layers”, re-save your artwork file, and then send us.

We request you avoid submitting your font’s separately from your file because we don’t want that any problem create in our printing process.

We highly recommend you to save all the images properly. Our graphic designer works closely with you and tries to guide you properly. But you need to save your images properly and before your file reaches us it should be completed with clear images, proper font, and high quality of resolution. If you find your images are missing we ask you to resave your file so we don’t miss anything while printing. Some software like illustrator and other suchlike mostly drop the image. Therefore, you need to be careful. If you are working in Photoshop, then we suggest you save files properly before doing ok anything there.

Normally we need 300 dpi resolutions but it depends on the nature of the files. For example for big posters and banners we recommend 12000 dpi also. The sharper the resolution, the better the printing result would be. ( can be expected).

A high resolution for your image is very important. We recommend 300 dpi resolutions for your image. Dpi means dots per inch. If there are more dots per inch, it gives a clear and sharper look to the picture. Your files need to be 300 dpi if it’s not of that quality you will be unable to increase the resolution by applying other techniques like increasing the dots per inch.

Knowledge Center

The outlook and appearance matter the most in the era we are living. The beautiful appearance attracts the people, the same is the situation with the beautiful packaging, it catches the attention of clients and influences them to buy it. Moreover, the bright colors and high-quality graphics are used while producing packing boxes. All the boxes provided are at reasonable and affordable rates. If you want to place your order or have some queries kindly visit our website https://www.clawscustomboxes.com/.

Customized gift boxes can work for any organization however best with those that sell sweet candies, garments, or toys. These become a significant bit of bundling to have close by during business occasions, occasions, and birthday events when customers are searching for wrapping alternatives for presents. You can request any design, logo, color, text on a gift box with a motive that the gift box will bring a smile on the face of your loved ones and will stand out among other gifts. Moreover, your gift box should be appealing enough that the people want to know what’s inside it. If you want to order a custom gift box to please your loved ones visit our page https://www.clawscustomboxes.com/.

Retail packaging is the most important tool if you want to increase your selling level. It not only helps in the promotion of the brand but also attracts the clients towards it. You should go for an eye-catching packing that will help you in acquiring the trust of customers. If you want the publicity of your brand and wants to achieve all the objectives we are here or you. Our team will guide you in every step.

The following are the advantages of eco-friendly packaging boxes.

- These packaging boxes do not have any harmful impacts on the environment.

- Business reputation increases by the use of eco-friendly packaging boxes.

- Blister packs and eco-friendly not only reduces the use of plastic in the product but also cause less harm to the environment.

- The soy ink is used in the manufacturing of eco-friendly packaging boxes which not only good for our earth but also offers brighter colors. Also, it has less amount of volatile organic compounds that affect our ozone and environment.

Countertop Display Box is made up of corrugated cardboard. It is specifically designed to sit on the top of the counter in spite of the fact that they do particularly well approach the point of sale and also include different areas that were designed to hold stuff like toys, DVDs, Books, and CDs.

Folding cartons are specifically designed to grab the attention of customers. They not only provide information but also provokes the emotions of clients. Our professional team will be there for you. They will guide you in every step. Also, through their creative skills, clients are attracted to your brand.

SBS stands for Solid Bleached Sulfate. It is a very costly and high quality of paper board substrates. Now you must be thinking what makes it expensive and high quality? Well, the answer is the manufacturing process and substrates used. It is manufactured by using bleached virgin wood pulp. It is used in high-end packaging to ensure that it has great quality and also in food, beverages packaging where it acts as a moisture barrier. Moreover, this high-quality paper board substrate can also be used in the box packaging of cosmetics, health, and medicines.

A template is basically a vector form that helps in figuring out the layout of the packaging. The template gives the idea of the final shape of the product so it can be molded in case it has any problem.

You can order the template of any size or shape. Sometimes the making of the template is based upon the number of panels. The most popular templates include the Accordion and Tray card templates. As they can hold a lot of information.

Templates can be customized in any software including the Adobe PDF, Microsoft Word, Adobe In Design and Quark X Pres.

It stands for Clay Coated Light Black. Just like the CCNB paper, both sides are coated with clay and are light gray.

CCNB stands for Clay Coated News back. It is made up of clay that is coated on both sides including the specific fiber type. It is usually brown or gray in color.

What is meant by the Recycled paper board when it comes to the printing and packaging industry? Recycled paper board is a sort of paper board created utilizing recuperated squander from paper, along these lines changing over purchaser sources just as plants to meet creation necessities. The last item is viewed as an increased substrate and has somewhere in the range of six and nine utilizes. Choosing a reused paper board is progressively moderate, making it a financial option for standard paper board inside the bundling business.

White cardboard boxes also known as ivory boards are made utilizing the strong white cardboard that is manufactured using high-quality pure wood pulp which is certainly thick. It is lead with calendaring or embossing. And is used frequently utilized for wrapping and certificates, trademarks, business card, invitation, and packaging decoration. Its quantity within 210 to 400 gsm.

PMS Color:

PMS color stands for Pantone Matching System. It is used for printing spot colors as they are printed by using the extraordinary ink. The printing is indicated dependent on its Pantone number or name inside a shading graph. It permits the colors to show up exactly as expected once printed rather than how they show up on a PC screen.

Process Color:

Process color also is known as CMYK. CMYK stands for four colors Cyan, Magenta, Yellow, and Black. These four colors are very important in the printing process by mixing these colors together and give rise to other colors which are used in printing. It is the most common type of which is used in the printing and packaging industry.

Die line is the package template that makes sure a printed product is arranged properly. The diagram is an ultra finest representation of each of the fold and cut lines pieces in the Packaging or is on the box, pocket folders, and envelopes. Creating precise die lines involves certain steps.

Some times a client himself sends a desired packaging example to the print company. Then the company would then take apart the sent package to indicate graphics and tucks and take dimensions. When there is a product but no packaging, the dimensions are taken for the actual product instead with wrapped paper added to estimate the size. After the dimensions, the software Adobe illustrator is utilized to create the die lines, by following the specific design or style standards. You would commonly take a test of hard copy of your created die line to make sure it’s working with the product. After you are done ensuring, it is now time to copy prototypes using materials like the paper with a heavyweight. After you are done checking the prototype for factors like sturdiness, the packaging then can be prepared for the shelves.

Following are the types of the recycled paper board exists in the packaging and printing industry:

- Clay Coated White Black(CCWB)

- Clay Coated Kraft Black(CCKB)

- Clay Coated Light Black(CCLB)

- Bending chip

- Clay Coated News Black(CCNB)

Products including Party favors, jewelry can be packaged in hexagon style boxes but with a high creativity level, you can fit any product in that package. Also, they are best when it comes to giving gifts to your loved ones and for decorations. The fascinating shape of the box appeals to the people towards it.

A custom box may refer to any container that has not been mass-created with the goal that it is made to fit the standard business sizes. At the point when you are making a custom box request, consider which shape and size will perfectly sync with your item. You can likewise include details like design, materials, colors, folds, bends, or any other thing. While ordering customized boxes always remember that these boxes can help you in appealing customers towards your brand.

The most ideal approach to meet your specific determinations for extraordinary bundling is to work intimately with a printing organization and its group. During the procedure, you will submit different drafts to help transform your imagination into reality through the work of your team. If you need more information or have some queries visit https://www.clawscustomboxes.com/.

A custom box may refer to any container that has not been mass-created with the goal that it is made to fit the standard business sizes. At the point when you are making a custom box request, consider which shape and size will perfectly sync with your item. You can likewise include details like design, materials, colors, folds, bends, or any other thing. While ordering customized boxes always remember that these boxes can help you in appealing customers towards your brand.

The most ideal approach to meet your specific determinations for extraordinary bundling is to work intimately with a printing organization and its group. During the procedure, you will submit different drafts to help transform your imagination into reality through the work of your team. If you need more information or have some queries visit https://www.clawscustomboxes.com/.